For 125 years, J.A. Becker & Söhne has been a recognized partner of industry and trade. With 140 employees, the company today offers its customers state-of-the-art problem solutions in the fields of compressed air and lifting technology. The product range includes piston compressors from 20 to 400 bar for air and gases as well as the entire field of compressed air preparation. The focus of the lifting technology product area is on hydraulic repair and maintenance lifting platforms for cars, trucks and rail vehicles as well as on the development of individual problem solutions. The flexibility of a medium-sized company combined with high quality standards, customer-oriented planning, development, manufacturing and a complete range of services makes J.A. Becker & Söhne a competent partner for a wide range of users worldwide.

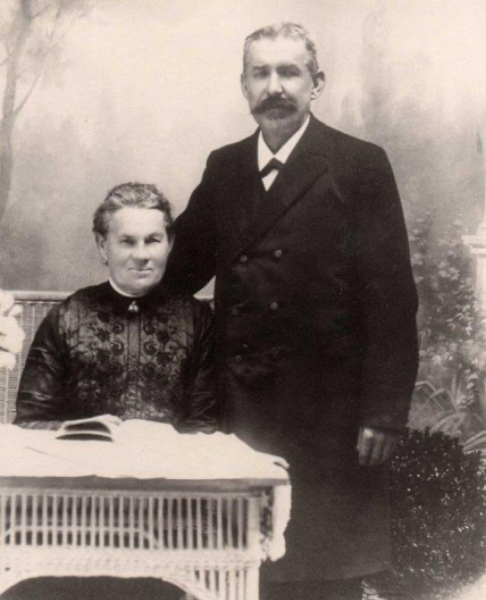

The company J.A. Becker & Söhne was founded in 1897 by Jacob August Becker as a craft enterprise. They performed locksmith work as a service for the local industry. Already at the beginning of the last century the serial production of spindles for manufacturers of woodworking machines was started. Only a few years later, the previous subcontracted part was turned into its own final product: Fruit and grape presses. At the end of the twenties, hydraulics was used as a further development of the mechanical spindle. It was obvious to use the power of hydraulics not only for pressing but also for lifting. Thus, at the beginning of the thirties, the production of the products that are still typical of the company was started.

The development of the lifting platform kept pace with the development of the automobile, so that in today’s delivery program of the now oldest, still existing lifting platform factory in Europe, a complete lifting program, for passenger cars up to the heaviest special vehicle, is available.

Parallel to the development of the lifting platforms, the design and manufacture of compressors took place. Today, the range extends from small handyman compressors to industrial compressors, for example, for driving electrical high-voltage switches or for filling breathing air cylinders for diving and disaster services.

In recent years, JAB has specialized in particular in high-pressure compressors for nitrogen compression and for vehicle refueling in natural gas tank systems.